Why Polypropylene (PP) Became the Standard Material for Modern Stationery

Over the past several decades, the stationery industry has evolved from paper-based folders and cardboard files to more durable, flexible, and long-lasting materials. Among these, polypropylene (PP) has emerged as one of the most widely adopted materials in modern stationery manufacturing.

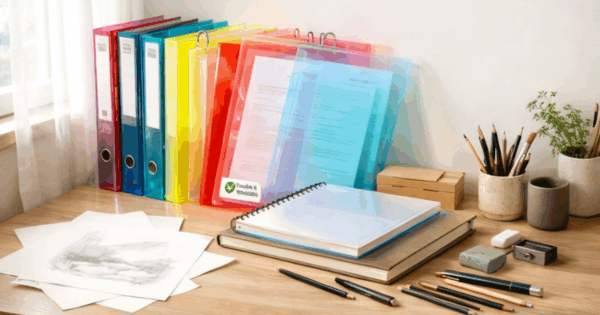

Today, PP is used in a broad range of products — from folders and expanding files to ring binders and document sleeves — supporting the growing need for reliable document storage in offices, schools, and professional environments.

The Evolution of Stationery Materials

In the 1970s, most document storage products relied on paperboard or cardboard. While cost-effective, these materials wore down quickly, especially with frequent handling. As office environments expanded and document management became more complex, durability and reusability became more important.

Polypropylene entered the market as a lightweight, flexible plastic that addressed many of these limitations. Its resistance to moisture, tearing, and deformation made it suitable for long-term use, marking a significant shift in how stationery products were designed.

Expansion Through the 1980s and 1990s

By the 1980s and 1990s, PP folders, expanding files, and ring binders became widely adopted. As corporate offices and educational institutions handled increasing volumes of printed documents, demand grew for materials that could withstand daily use while maintaining a professional appearance.

During this period, document organization shifted from temporary filing toward more systematic, long-term storage solutions — a change that supported the continued growth of PP-based products.

The 2000s: Design, Customization, and Branding

In the early 2000s, attention moved beyond basic durability toward design and customization. PP stationery products began appearing in a wide range of colors, textures, and finishes. Organizations sought document storage tools that aligned with brand identity while maintaining practical performance.

This flexibility in design further reinforced PP’s position as a preferred material in both corporate and educational environments.

Material Advantages That Sustain PP’s Popularity

Polypropylene continues to be widely adopted in stationery manufacturing because it balances durability, practicality, and material efficiency. Its physical properties make it suitable for products that are handled frequently, transported regularly, and expected to maintain performance over time.

Durability for Repeated Use

PP offers strong resistance to tearing, cracking, and surface abrasion. Unlike paperboard materials that weaken with moisture or repeated bending, PP maintains structural integrity even after prolonged handling. This makes it particularly suitable for folders, expanding files, and document sleeves that are opened and closed daily.

Its flexibility also helps reduce stress marks along folds or hinges, extending product lifespan in high-use environments such as schools and offices.

Lightweight Structure

Despite its strength, PP has a low material density, which allows manufacturers to produce sturdy products without adding unnecessary weight. This is especially important for document storage items that may be carried in bulk or transported frequently by students, administrative staff, or professionals.

Lightweight construction also reduces shipping weight in large-volume distribution, supporting more efficient logistics.

Moisture and Surface Resistance

PP does not absorb water like paper-based materials, making it less prone to swelling, warping, or surface deterioration when exposed to humidity or accidental spills. Its smooth surface also resists staining and can be easily cleaned, which is beneficial in environments where materials are shared or reused.

This resistance contributes to longer product life and improved document protection during daily use.

Recyclability and Material Efficiency

As a recyclable thermoplastic (resin identification code #5), PP can be reprocessed and reused in manufacturing cycles, which supports material recovery and waste reduction. Compared to laminated paper products or certain alternative plastics, PP often requires less material thickness to achieve the same strength, improving material efficiency.

Its durability also encourages reuse over replacement, further reducing long-term material consumption.

Common Applications of PP in Stationery

PP is widely used in products such as:

-

Standard document folders for daily filing

-

Expanding files for bulk document storage

-

Envelope-style folders for document transport

-

Ring binders and presentation formats

-

Protective sleeves and organizers

These applications span offices, schools, healthcare environments, and professional service industries.

PP materials are also widely used in structured document presentation and storage systems designed to keep contents organized and protected.

Industry Trends Supporting Continued PP Use

As workplaces adopt hybrid models and mobility increases, stationery solutions are expected to be durable, portable, and reusable. Many of these requirements are reflected in modern portable art organizer bags used for document and material transport. The combination of strength, light weight, and design flexibility allows PP to meet these expectations across different industries.

Additionally, organizations seeking longer-lasting supplies and recyclable material options continue to favor PP-based products for everyday document management.

Conclusion

Polypropylene’s rise in stationery manufacturing reflects broader changes in how documents are stored, transported, and managed. Its balance of durability, flexibility, and recyclability has made it a standard material across modern office and educational environments.

As document organization continues to evolve, PP remains a practical material supporting both functional performance and long-term usability.